Blogi: Exploring Robots and Code - REDU collaborates on 3D Printing Seminar with TAMK

30.6.2025 julkaistuBringing Together Experts in 3D Printing and Visual Programming

Earlier this month, REDU took part in a seminar held in Tampere focused on large-scale 3D printing, visual programming using Grasshopper, and the integration of IoT applications in 3D printing using the Fiware platform. The event, organized by Tampere University of Applied Sciences (TAMK) in collaboration with REDU, was part of the nationwide 3DTY project, which aims to develop and disseminate expertise in large scale 3D printing, and support its adoption in Finnish industry.

The seminar offered both in-depth technical insights as well as hands-on tools for robotic 3D programming and printing. Participants included educators, professionals, and students from around Finland, all interested in exploring new tools, methods, and collaborative approaches in digital manufacturing.

Day 1: Visual Programming in Practice at TAMK Robotics Lab

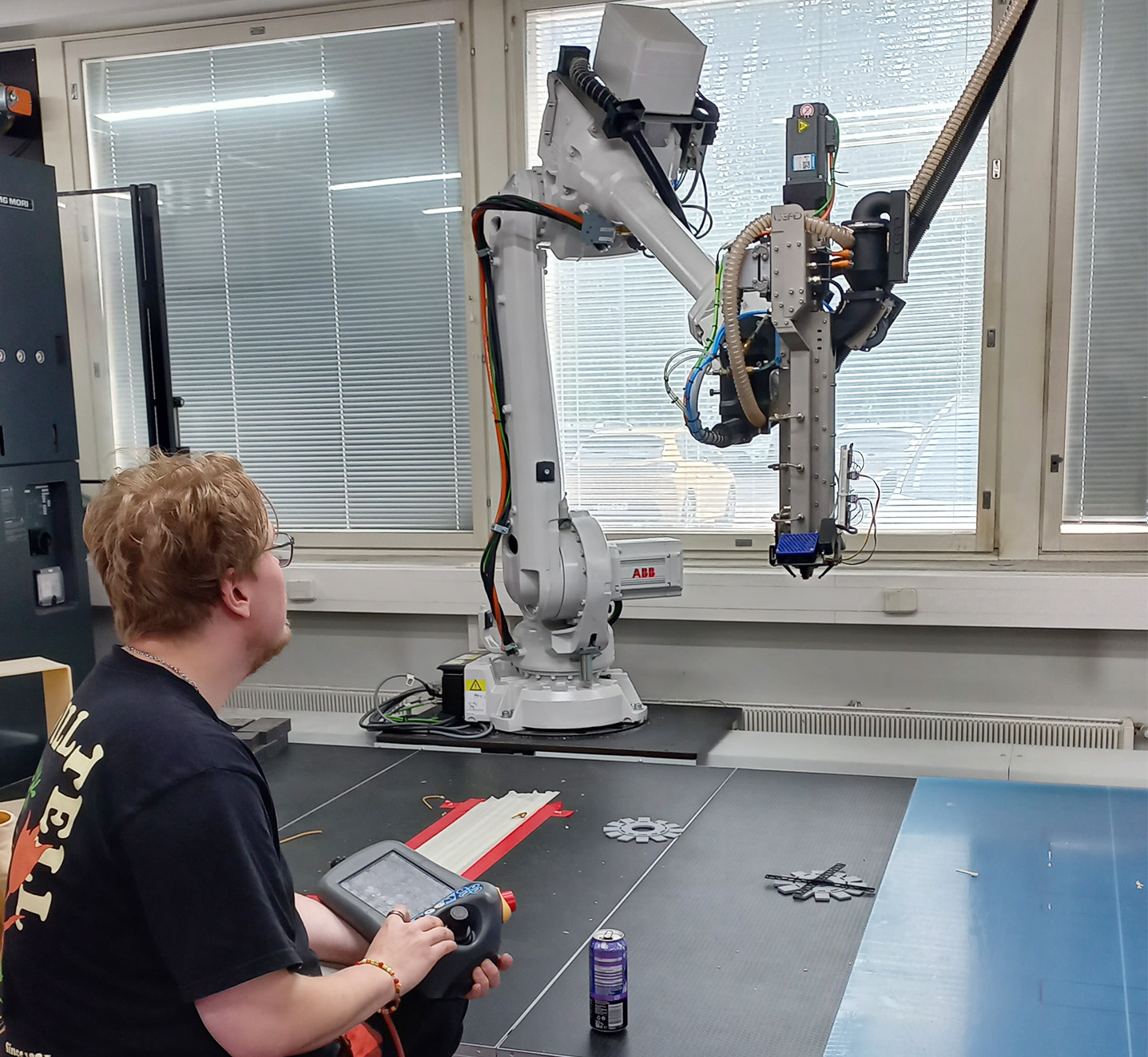

The first day was spent at TAMK’s impressive robotics lab, where REDU’s Severi Salmirinne and Maxim Narbrough worked alongside TAMK’s Auni Karja and Marco Peltonen. Initially, each team demonstrated their particular workflows and software solutions. The focus then shifted to integrating Grasshopper—a visual programming tool for Rhino3D—into robotic 3D printing workflows, customized for testing on the lab’s robotic cell.

Working with the advanced 3D printing cell at TAMK, the group explored different ways of designing and controlling toolpaths, material flow, and print strategies. The session allowed both teams to explore new programming methods and gain a deeper understanding of how visual programming can be adapted to different robotic cells for digital fabrication.

Image: Robotics specialist Marco Peltonen demonstrates the programming of the advanced robotic cell at TAMK.

Day 2: 3DTY Grasshopper and Data Seminar at TAMK

The second day featured an engaging series of talks and workshops from professionals working across design, materials development, and manufacturing.

Highlights included:

- Eve Saarekoski (Development Manager at KCL) – Shared insights into the development and use of Formi 3D materials, including REDU’s R&D projects.

- Jesse Pietilä (Interior Designer) – Presented his design for a 3D-printed speaker and discussed design considerations for additive manufacturing.

- Laurent Delrieu (Aerospace Engineer and Grasshopper Specialist) – Detailed his advanced techniques for continuous toolpath design using Grasshopper.

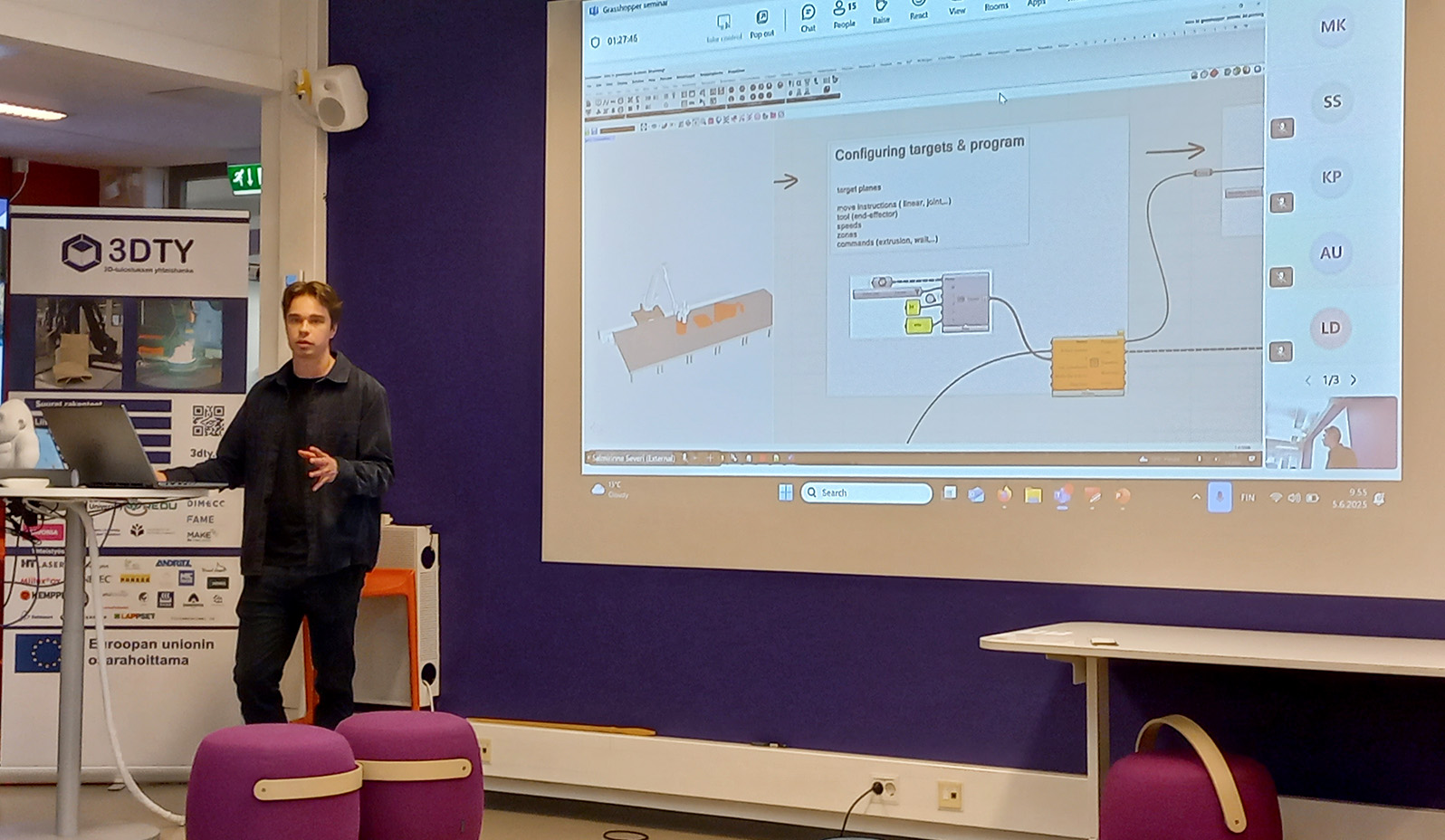

- Severi Salmirinne (Visual Programming Specialist) - Introduced the process of creating customized programs for controlling robotic cells for 3D-printing.

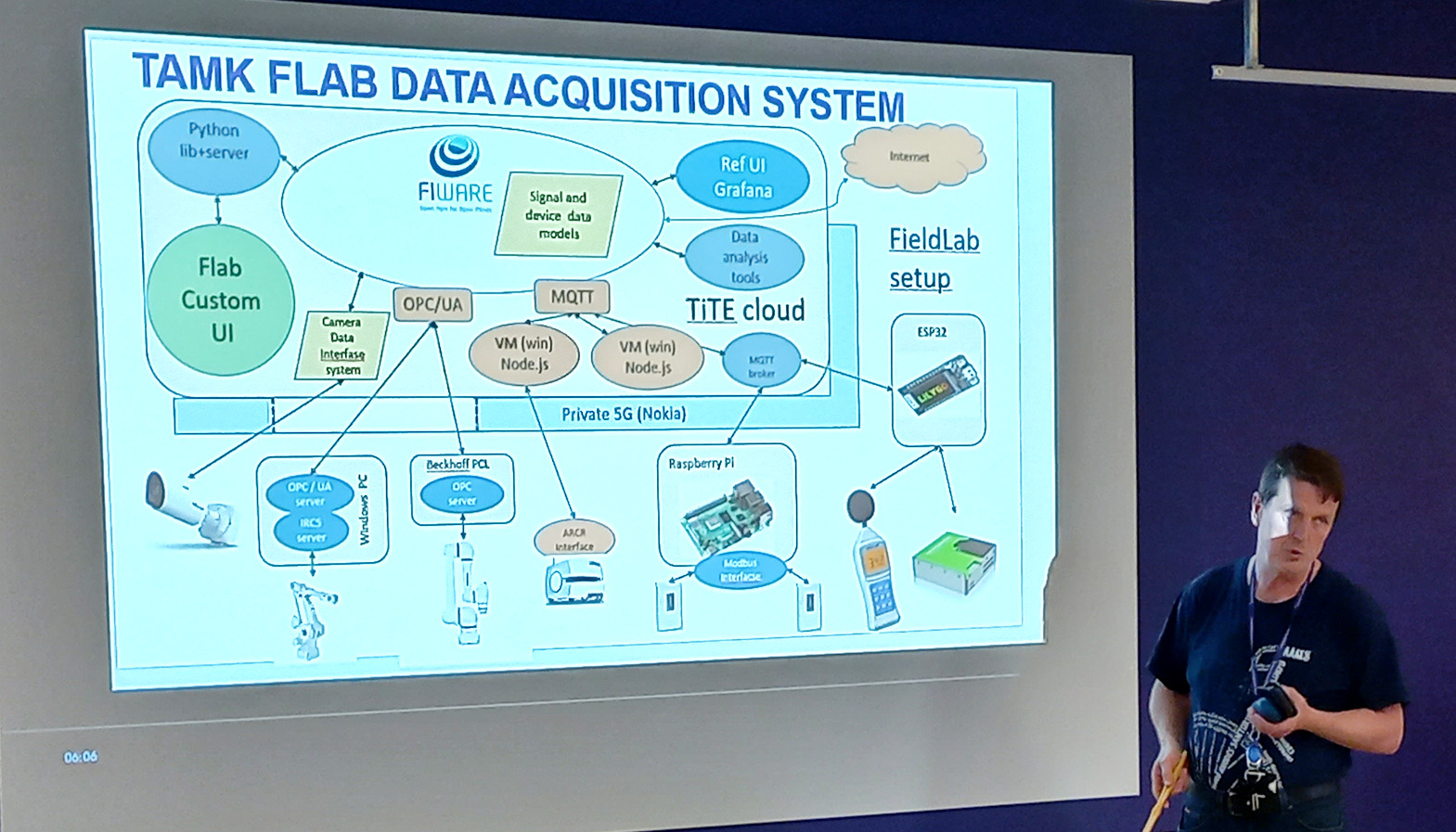

Integrating IoT Data in Manufacturing with Fiware

In their afternoon session, Jere Siivonen and Kari Naakka demonstrated how the open-source Fiware platform can be used to collect, analyze, and integrate sensor data into manufacturing processes. Their presentation highlighted practical applications of Fiware for real-time monitoring and smart automation, showcasing its potential in real-time monitoring and feedback in additive manufacturing applications.

Image: Kari Naakka and Jere Siivonen showed how sensor data can be harnessed using the Fiware platform.

Image: Kari Naakka demonstrating real-time sensor data collection and use in robotic 3D-printing.

Hands-on Visual Programming Workshop

In addition to his presentation, REDU’s own Severi Salmirinne also led a practical workshop that walked participants through the setup, simulation, and customization of robotic 3D printing tasks. The fast-paced session gave attendees the chance to try out key parts of the workflow, and to understand how Grasshopper’s parametric design tools can be applied in real-world settings for different robotic cells.

Image: Severi Salmirinne sharing his expertise in visual programming for 3D printing using Grasshopper.

Based on the feedback from participants, there was a clear interest among many to test and adapt the capabilities of these workflows to their R&D projects. With this in mind, REDU’s team aims to offer more extensive training workshops at a later date.

Collaboration and Learning at the Core

Collaboration with TAMK was highly rewarding and enjoyable, and the seminar served as an excellent forum for sharing practical knowledge and supporting skill development in advanced manufacturing technologies. These kinds of events are an important part of REDU’s ongoing commitment to integrating R&D and vocational education with real-world innovation.

The 3DTY project consistently fosters meaningful collaboration between academic institutions and industry partners, equipping students and professionals with the skills and knowledge needed to meet the dynamic challenges of today’s additive manufacturing landscape.

Many thanks to all who participated, especially to Anne Seppälä and Tero Haapakoski for organizing and hosting an inspiring event. We look forward to further collaborating with their fantastic team!

Maxim Narbrough

Project Manager, 3DTY - printing collaboration project